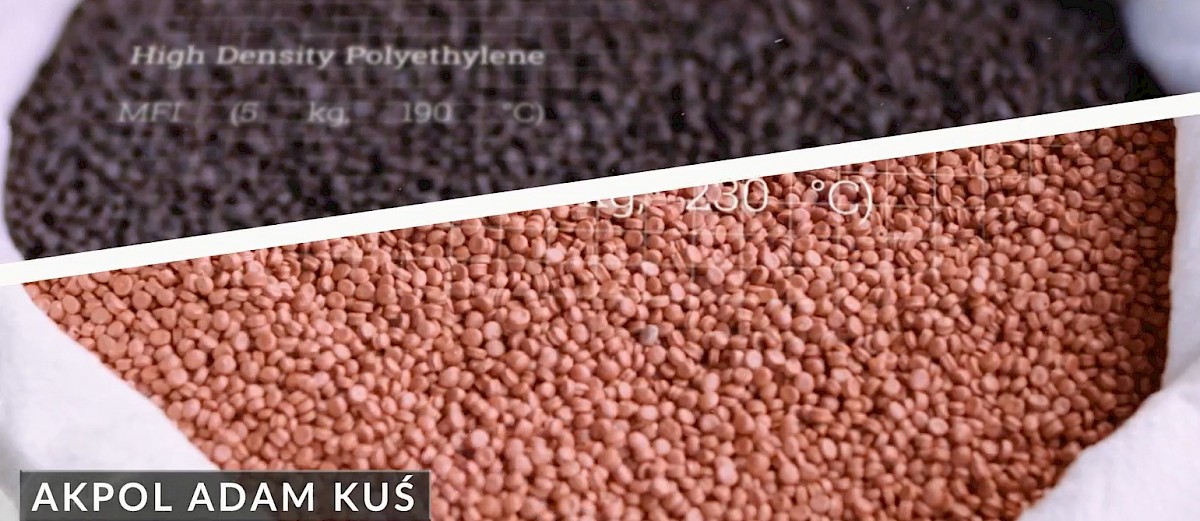

The project objective is to improve competitiveness of AKPOL ADAM KUŚ Company by means of implementation of the R&D output that is the innovative manufacture technology for Monochromatic Sealable Polyethylene Granules. The manufacture technology for monochromatic sealable polyethylene granules, including efficient removal of pigments and heat-sealing substances will be based on automatic solid waste colour-related sorting line that is characteristic of much higher capacity and quality than a manual sorting process. In effect, the standard of the recycled polyethylene purity degree will be higher, and efficient removal of the chemical heat-sealing substance will be ensured. Furthermore, the polyethylene granules will achieve heat-sealing properties, ensuring high quality and purity of the final product.

The innovative manufacture technology for Monochromatic Sealable Polyethylene Granules will allow for: higher capacity, cheaper, and more efficient manufacturing of the monochromatic fraction - manufacturing the granules of the relevant purity degree, which will make it possible to significantly upgrade the manufacture technology for the heat-sealing granules that do not require chemical additives (better quality of the product for reduced manufacture costs). The product target group includes both the domestic foreign customers. The target group is comprised of the manufacturers of a variety of plastic products.

Project managment: AKPOL ADAM KUŚ

Project title: Wdrożenie technologii produkcji termozgrzewalnego regranulatu polietylenowego o jednorodnej barwie – MSPG (Monochromatic Sealable Polyethylene Granules)

Number: 3.7 Wzrost konkurencyjności MŚP

Project number: RPLU.03.07.00-06-0338/16

Project costs: 3 647 707,89 PLN

EU dotation: 2 965 616,17 PLN